Use the G-Force Calculator below to calculate the force exerted on samples in a centrifuge. You should always set your centrifuge to the correct G-Force, as recommended by your tube manufacturer. Follow the programming instructions of your centrifuge manufacturer. You can calculate G-Forces using either inches or centimeters for the radius of the centrifuge.

How to Calculate G-Force:

The Force exerted on a sample in a centrifuge is a function of the rotation speed of the centrifuge (RPM) and the radius of the rotor.

If you know the RPM, the equations to calculate G-Force are:

In Centimeters: RCF or G-Force = 0.00001118 x Rotor Radius x (RPM)²

OR

In Inches: RCF or G-Force = 0.0000284 x Rotor Radius x (RPM)²

How to Calculate RPM:

If you know the G-Force you need and you want to calculate the RPM, the equations to calculate the RPM are:

In Centimeters: RPM = sqrt(G-Force / (0.00001118 x Rotor Radius))

OR

In Inches: RPM = sqrt(G-Force / (0.0000284 x Rotor Radius))

Measuring Centrifuge Rotor Radius

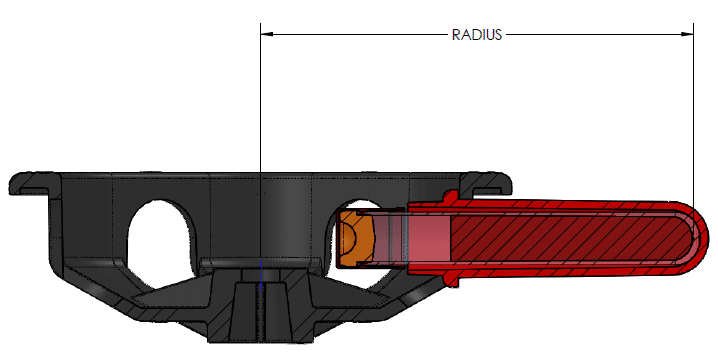

The Rotor Radius is the radius of the rotation measured in centimeters or inches. For example, in the photograph below – The Rotor Radius is 12.7 cm.

Revolutions Per Minute

RPM stands for “revolutions per minute.” This is how centrifuge manufacturers will communicate and display how fast your samples are rotating around the axis of the rotor. However, even at the same RPM, the centrifugal force applied to your samples can vary as a function of the Radius of the rotor. So, even when spinning at the same RPM, a larger Radius will produce larger forces just as a smaller Radius will produce smaller forces.

For example, when revolving at 3,500 RPM, a large rotor with a radius of 15 cm will produce a maximum G-Force of 2,058 xg, while a small rotor with a radius of 5 cm will produce a maximum G-Force of 686 xg.

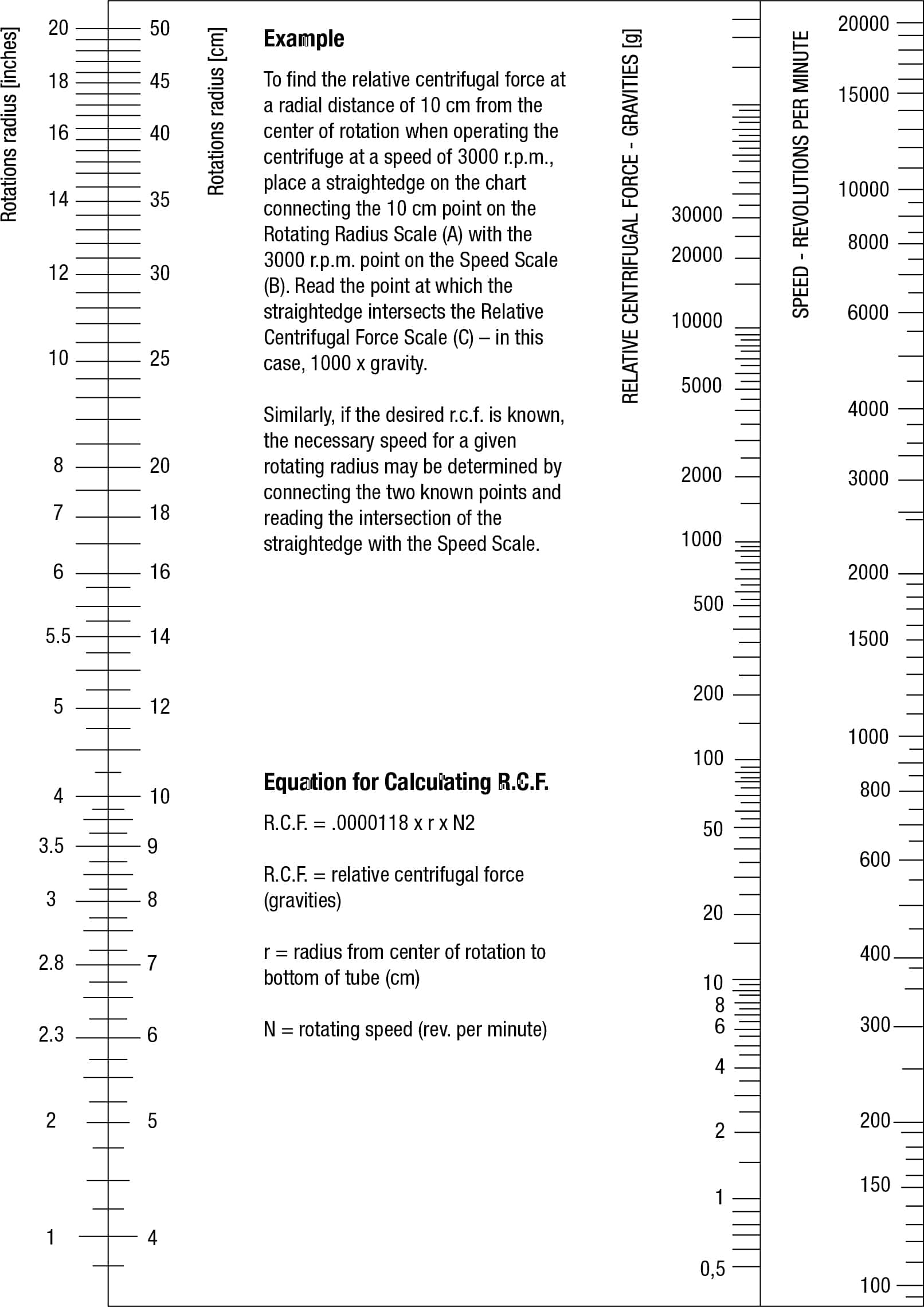

If you prefer to use a Nomograph to calculate your RPM or G-Force, one is provided below. Once you know what G-Force you need to spin your samples at, you can measure the radius of your centrifuge rotor and calculate the RPM using the equations provided above or by using the Nomograph found below.

You may also use the equations provided above if you prefer to use the equations to the Nomograph.

G-Force Calculation Summary for Centrifuges

In summary, you should always set your centrifuge to the correct G-Force, not by an assumed RPM. Most clinical tube manufacturers will provide Instructions for Use that specifies the recommended G-Force for their tubes. For your convenience, you can find the I.F.U. for the most common brands here.

Some centrifuges will use a display to present RPM and G-Force. In this case, you can easily set the centrifuge by G-Force without doing the calculations. If you are using a centrifuge that does not display G-Force and you are executing a protocol with one or more G-Force requirements, you will need to calculate the RPM that achieves the required G-Forces and set the centrifuge by the RPM display.

Find a Centrifuge to Suit Your Needs

High G-Force STAT Centrifuges

- STAT blood, chemistry, and PPP

- Horizontal or fixed angle

- 4,400 max xg

- 6, 12, and 24 tube capacity

Programmable Routine Centrifuges

- Chemistry, coag, and urine

- Horizontal or fixed angle

- 2,000 max xg

- 6, 12, and 24 tube capacity